We’ve designed and built power units for over 60 years for use in a wide-range of industries. Each system is designed for a customer’s specific application of motion and control technologies. System up-time matters, so reliability and maintainability are requirements every time. Our design philosophy takes into consideration the real world abuse that hydraulic systems will endure. The scope of each project is tailored to match the customer’s needs in order to provide the most appropriate and cost effective solution.

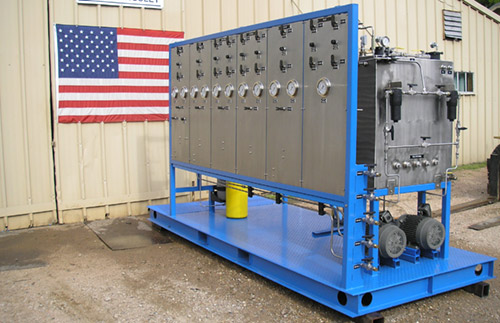

Types of systems include industrial hydraulic stationary plant applications, mobile high pressure hydraulic truck and trailer applications, and portable power packs.

Some of the applications and industries we’ve built power units for include bolt torquing and tensioning, non-destructive testing, well servicing, rig hydraulics, power generation, and all sorts of pressing, stretching, molding, swaging, and forging applications.

Areas of specialization include high pressure systems and alternative fluid systems for different energy industry segments including oil and gas and wind energy.

Capabilities include design, engineering, fabrication, machining, assembly, and testing.

Systems are designed around the unique performance requirements of each application. Each hydraulic circuit is designed to take into account the application’s specific demands for horsepower, pressure, flow, duty cycle, operating environment, controls, and other special considerations.